scratch test standard|astm g171 03 : custom This document specifies a test method for determining under defined conditions the resistance of a single coating or a multi-coat system of paint, varnish or related product to penetration by scratching with a scratch stylus loaded with a specified load. Idea Áudio Studio em Plano Diretor Sul. (0) Avaliações. Avalie esta empresa. Estúdio de gravação e ensaios. Quadra 712 Sul Alameda 5, 19 QI-4. Plano Diretor Sul - Palmas - TO. Info.

{plog:ftitle_list}

WEB15 de mar. de 2021 · O jogo permite que jogadores vivenciem confrontos na região da cidade soviética, experimentando a ação de guerrilha que mobilizou os exércitos soviético e nazista entre julho de 1942 e 1943.

This document specifies a test method for determining under defined conditions the resistance of a single coating or a multi-coat system of paint, varnish or related product to penetration by scratching with a scratch stylus loaded with a specified load.

In ASTM D7027-13, the method outlines a strict procedure for assessing the scratch resistance of polymer surfaces. It utilizes an instrumented scratch machine, following the guidelines of the standard. This procedure is crucial for . ASTM G171-03 (2017) Standard Test Method for Scratch Hardness of Materials Using a Diamond Stylus. Significance and Use. 5.1 This test method is intended to measure .This test method is able to characterize the scratch resistance of polymers by measuring many significant material parameters. The scratch-inducing and data acquisition process is .

1.1 This test method describes a laboratory procedure using an instrumented scratch machine to produce and quantify surface damage under controlled conditions. This test method is able to .

1.1 This International Standard specifies a method for determining the scratch properties of plastics under defined conditions. The method involves making a scratch by moving a hard instrument (scratch tip) of specified geometry under .This document specifies a test method for determining under defined conditions the resistance of a single coating or a multi-coat system of paint, varnish or related product to penetration by . The ASTM C1624 test standard (Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Scratch Testing) provides comprehensive and detailed .

This test method describes a simple and rapid evaluation of a coated material’s resistance (film’s hardness) to scratch effects due to the sliding of pencils of various hardness (6B to >6H), . In many cases, the scratch test has now become accepted as a versatile tool for assessing the mechanical integrity of a surface, whether bulk or coated, and has found .

The Scratch Test: Calibration, Verification and the Use of a Certified Reference Material N M Jennett and S Owen-Jones Measurement Good Practice Guide . (The uncertainty in an average is the standard deviation of the values averaged multiplied by tn/√n). n is the number of measurements, .

Standard Test Method for Scratch Hardness of Materials Using a Diamond Stylus 1 This standard is issued under the Þxed designation G171; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A The first introduction of the scratch test as a qualitative method of measuring coating adhesion was in the 1950s by Heavens [1] who applied a constant load to the sample surface via an indenter in order to damage the surface by scratching and induce delamination of the film.The applied loads that created specific damage, especially cracks or delamination, . Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing. . 5.3 The quantitative coating adhesion scratch test is a simple, practical, and rapid test. However, reliable and reproducible test results require careful control of the test system configuration and .Standard test method for Scratch hardness ASTM D7187 Standard test method for measuring mechanistic aspects of scratch mar behavior of paint coatings by nano scratching. ASTM D7027 Evaluation of scratch resistance of polymeric coat-ings and plastics using and instrumented scratch machine. ASTM C1624 Standard test for adhesion strength and .

The adhesion strength measured by scratch testing of sol-gel fluorinated hydroxyapatite (HA) coating applied in Ti 6 Al 4 V titanium alloy has shown marked improvement with an increase in firing temperature (Zhang et al., 2006).While the average adhesion strength of a nonfluorinated HA coating cured at 500°C was found to be 0.37 N which rose to 0.47 N when cured at 700°C, .

scratch test used for what

Mohs hardness test: When conducting the test, place the unknown specimen on a table top and firmly hold it in place with one hand. Then place a point of the reference specimen against a flat, unmarked surface of the unknown specimen. Press the reference specimen firmly against the unknown, and deliberately drag it across the flat surface while pressing firmly.

Multi-Finger Scratch/Mar Tester . Individual weights of varying loads mount to the top of each arm finger to exert a standard force on the surface of the test material. Each instrument includes a weight set of 2N, 3N, 4N, 5N, 6N, 7N, 10N, 15N and 20N loads. Optional weights sets are also available consisting of either 4N, 8N, 9N, 12N or 8N .•Which ASTM wear or other International Standard Test provides quick, accurate and relevant results that correlate well with field use or experience? . Scratch Resistant Test Methods Test Results Abrasion Resistance Wear Tests Coatings (1) C1,1,1 C1,1,2 C1,2,1 C1,2,2 C2,1,1 C2,1,2 C2,2,1 C2,2,2 Test Units PC 7µm PC 13 µm PMMAStandard Test Method for Evaluation of Scratch Resistance of Polymeric Coatings and Plastics Using an Instrumented Scratch Machine1 This standard is issued under the fixed designation D7027; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision.

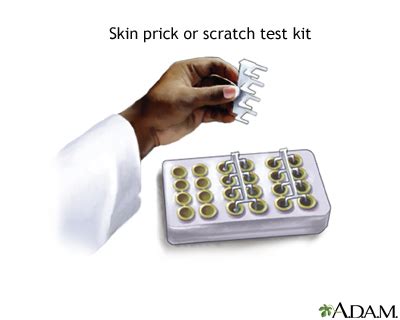

Skin prick (scratch) test. A skin prick test exposes your body to small amounts of possible allergens. It’s the most common type of allergy skin test. Providers use it to test for airborne allergies (such as pollen, dust, mold and animal dander) and food allergies. They may also use skin prick testing as an initial test for stinging insect .

1.1 This International Standard specifies a method for determining the scratch properties of plastics under defined conditions. The method involves making a scratch by moving a hard instrument (scratch tip) of specified geometry under specified conditions of load and speed across the surface of a test specimen and then assessing the result.Professional Automatic Scratch Tester - Precision Scratch Test for Research & Quality Management - Your Number 1 Partner Real values for our customers & clients . Engineered in accordance with international test standards including ASTM D2197, ISO 1518-1, ISO 1518-2, BS3900-E2 : Automatic Scratch Tester – Included items: Automatic Scratch . Significance and Use 5.1 Scratch tests are performed on specimens: (1) to evaluate the scratch resistance of a particular material, (2) to rank the relative scratch resistance of different materials, or (3) to determine the scratch coefficient of frictio This test method simulates the degree of wear and tear on the surface of a material under actual use to determine the quality and durability of the material. scratch resistance test is used in a wide range of industrial .

The Back Scratch Test, or simply the Scratch Test, measures how close the hands can be brought together behind the back.This test is part of the Senior Fitness Test Protocol, and is designed to test the functional fitness of seniors.Another shoulder flexibility test designed for testing the elderly is the Shoulder Circumduction Test.The synchronization of scratch data and 3D imaging ( Patent US 10,024,776 B2) is a unique and novel tool to study surface deformation and failures. Piezo actuator for precise down motion during scratch test. The best friction force . With DOE funding and in coordination with the ASTM Committees C28, G08, and B02, a new scratch adhesion test standard has been researched and written and has been published. The ASTM C1624 test standard (Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Scratch Testing) provides comprehensive and detailed .

Significance and Use 2.1 Mohs scratch hardness is a useful tool for determining a ceramic tile’s resistance to scratching. The resistance to scratching is determined based on a visual observation of the ceramic tile surface after an attempt to scratch the . Standard Test Method for Determination of Mohs Scratch Hardness C1895-20 ASTM|C1895 .STANDARD ISO 2409 Fifth edition 2020-08 . 7 Test specimen . it shall be ensured that all cuts mark or scratch the substrate. The depth of indentation into the substrate shall be as low as possible, however. The tools described in 5.2.2 and 5.2.3 are suitable for manual use, which is the more usual method of . The scratch stylus is usually a Rockwell C diamond with 200±10 μm tip radius, and the scratch-test method is described in the (prospective) European Standard prEN 1071-3 [1]. The reliability of the scratch-test method was investigated as part of a previous European project (FASTE) [2]. The main conclusion of that work was that variation in .Mechanical adhesion occurs by the coating adhering to the sanding scratch profile of the surface and by flowing around the fiber of the substrate to mechanically secure the film to the surface. . to assign a value to the adhesive properties of the coating. This procedure follows American standard test method (ASTM) — D2197, D2248, D2454 .

In this test, a scratch is made by a reference material of known hardness against the test sample, and if the scratch is visible, the reference material possesses higher hardness. To ensure accuracy, it is essential to perform the test on a clean and smooth surface with adequate pressure. Scratch kits are available, containing samples of Mohs . The origins of the automated scratch test came as a logical evolution of more basic industrial test methods, such as the knife test (ASTM D6677) [3], the tape peel test (ASTM D3359) [4], the pencil hardness test (ASTM D3363) [5], the pull-off adhesion test (ASTM D4541) [6] and the scrape adhesion test (ASTM D2197) [7]. Such methods are often .A skin prick test can take three to five minutes per allergen, plus the 15 to 20 minutes you wait to see if a reaction occurs. A patch test can also be about three to five minutes per allergen. With this test, you go home and come back a few days later for your provider to check for a reaction. An oral challenge test could take three or four hours.Paints and varnishes — Scratch test. Specifies a test method for determining under defined conditions the resistance of a single coating or a multi-coat system of paint, varnish or related product to penetration by scratching with a hemispherically tipped needle.

Conversely, the relationship between scratch test, scratch resistance, chemical composition and coating properties is more intricate. . Whereas the taber haze test is a standard test for mar resistance, one can also create micro-abrasion with a quick steel wool test. In order to minimize the influence of the operator, an adapted stoll .

scratch test definition

Resultado da APRESENTAÇÃO. Cetoconazol Shampoo é indicado para o tratamento da dermatite seborreica (caspa) em adultos, aliviando sintomas como coceira e descamação do couro cabeludo. Produto de uso externo (tópico), com fragrância suave de ervas. Conteúdo da Embalagem: 110ml.

scratch test standard|astm g171 03